Roll processing

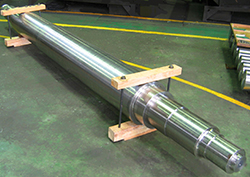

Our rollers and large-scale shafts for paper and film manufacturing produced with our high precision steel pipe processing technology accumulated over more than half a century have gained a high level of trust from paper and film manufacturers.

Manufacturing process

measurement

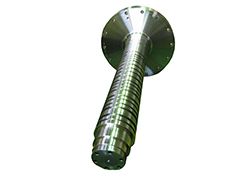

(Axle part finishing)

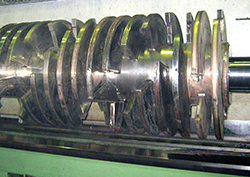

(Screw-thread cutting)

measurement

(Axle part finishing)

(Screw-thread cutting)

Main facilities

Please scroll sideways

| Machine name | Manufacturer | Processing capabilities |

Electrical- powered machines |

Units | Remarks |

|---|---|---|---|---|---|

| Extended long scale lathe | Yamazaki Mazak |

500φ×8000L | 11KW | 4 | |

| Extended long scale lathe | Yamazaki Mazak |

600φ×8000L | 11KW | 1 |

|

| Extended long scale lathe | Yamazaki Mazak |

500φ×6000L | 11KW | 1 | |

balancing machine |

Nagahama Seisakusho |

2100φ×10000L | 55KW | 1 | Diameter 2100 mm axis diameter 40-180 mm |

dedicated machine (BTA system) |

Dainichi Kinzoku |

900φ×12000L | 55KW | 1 | Roller internal finishing processing |

|

Boring dedicated machine (BTA system) |

Dainichi Kinzoku |

500φ×8000L | 44KW | 1 | |

|

Boring dedicated machine (BTA system) |

Dainichi Kinzoku |

450φ×8000L | 44KW | 1 | |

| NC lathe | Okuma Corporation |

500φ×700L | 45/57KW | 2 | Roller axle rough processing |

| Compact lathe | Yamazaki Mazak |

500φ×1500L | 11KW | 1 | |

| Extended long scale lathe | Dainichi Kinzoku |

700φ×12000L | 22KW | 1 | Roller external processing |

| Extended long scale NC lathe FNUCU 15T |

Dainichi Kinzoku |

700φ×12000L | 45/37KW | 1 | Roller axle parts Precision processing Roller diameter up to φ900 |

| Extended long scale lathe | Dainichi Kinzoku |

700φ×6000L | 22KW | 1 | |

NC lathe FUNUC 20T |

Dainichi Kinzoku |

900φ×12000L | 45/37KW | 1 | Roller external finishing |

NC lathe DL95 |

Dainichi Kinzoku |

600φ×7500L | 22KW | 2 | Roller external finishing |

| Boring dedicated machine |

Dainichi Kinzoku | 800φ×10000L | 37/30kw |

|

Manufacturing product categories

Paper rolls Canvas rolls Reel spool rolls Wire rolls Felt rolls General other paper rollers Export roller Winding roller Cylinder boring process Cylinder shaft

General lathe (internal and external trimming)

Main customers

[Paper manufacturing business]

Metso Paper Japan Co.,Ltd.

Mitsubishi Heavy Industries, Nippon Steel & Sumitomo Metal Corporation,

Kobayashi Engineering Works, Horikawa Engineering, Kinyosha Co., Ltd.,

Nomura Plating, Katsura Roller Manufacturing Co., Ltd.

[Industrial machineries]

Mitsui Engineering & Ship Bilding Co.,Ltd.

Hitachi Engineering and Services, Kubota, Kurimoto Steel, Teijin Engineering

(random order, honorific title omitted)